Our Polycrystalline Spinel products come from detonations of CDP formulations containing varying amounts of elemental magnesium, aluminum and dry ice.

Description: Grey abrasive powders

Composition: Approximately 95% oxides and the balance is carbon in various phases, including diamond. Some compounds are ferromagnetic. Here is the composition, according to CDP formulation:

| Percentage Magnesium in CDP Formulation | Percentage Aluminum in CDP Formulation | Spinel Content | Aluminum Oxide | Magnesium Oxide | Graphite and Diamond |

|---|---|---|---|---|---|

| Balanced for Spinel | Balanced for Spinel | 95% | <1% | <1% | 3% - 5% |

| Lower | Higher | <95% | >1% | 0% | 3% - 5% |

| Higher | Lower | <95% | <1% | >1% | > 5% |

This chart shows that we can control the ratios of spinel, magnesium oxide and aluminum oxide according to the amount of elemental magnesium and aluminum used in the detonatable CDP formulation. Acid digesting the byproducts removes all magnesium oxide.

By adding additional magnesium to the formulation than what is necessary to make spinel, we produce the same amount of graphite/diamond in the byproduct, however, this also produces spinel plus a controllable amount of magnesium oxide. By acid digesting the magnesium oxide away we directly customize the product’s overall carbon content.

Adding more aluminum than what is necessary to make spinel generates spinel, additional aluminum oxide, no magnesium oxide and the same 3 – 5% graphite/diamond. Since aluminum oxide is harder than spinel, we can customize the hardness of the non-carbon phase through adding more aluminum.

Particle Size Distribution:

| Type | d10 | d50 | d90 | Surface Area m²/kg | Graphite and Diamond |

|---|---|---|---|---|---|

| Bulk Material (-90 µm) | 7.1 µm | 16.8 µm | 35.6 µm | 450 | 3% - 5% |

| Micronized #1 | 1.2 µm | 3.2 µm | 7.0 µm | 3000 | 3% - 5% |

| Micronized #2 | 1.0 µm | 2.8 µm | 5.4 µm | 3800 | 3% - 5% |

| Micronized #3 | 0.9 µm | 1.8 µm | 3.1 µm | 3900 | 3% - 5% |

Safety: Non-toxic; not hazardous; use appropriate breathing protection when handling this product in its dry state.

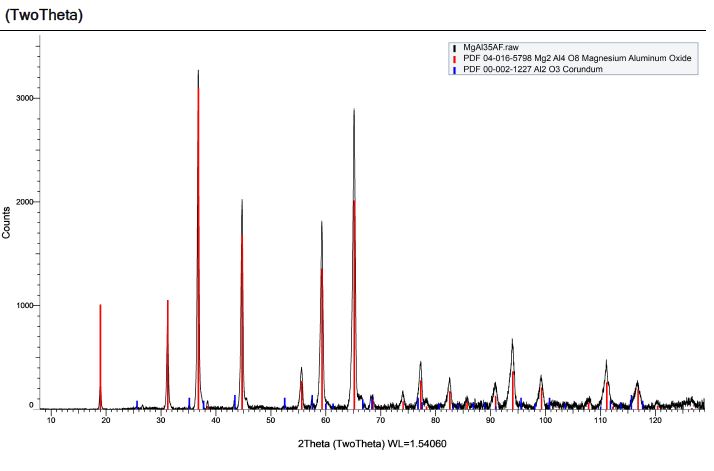

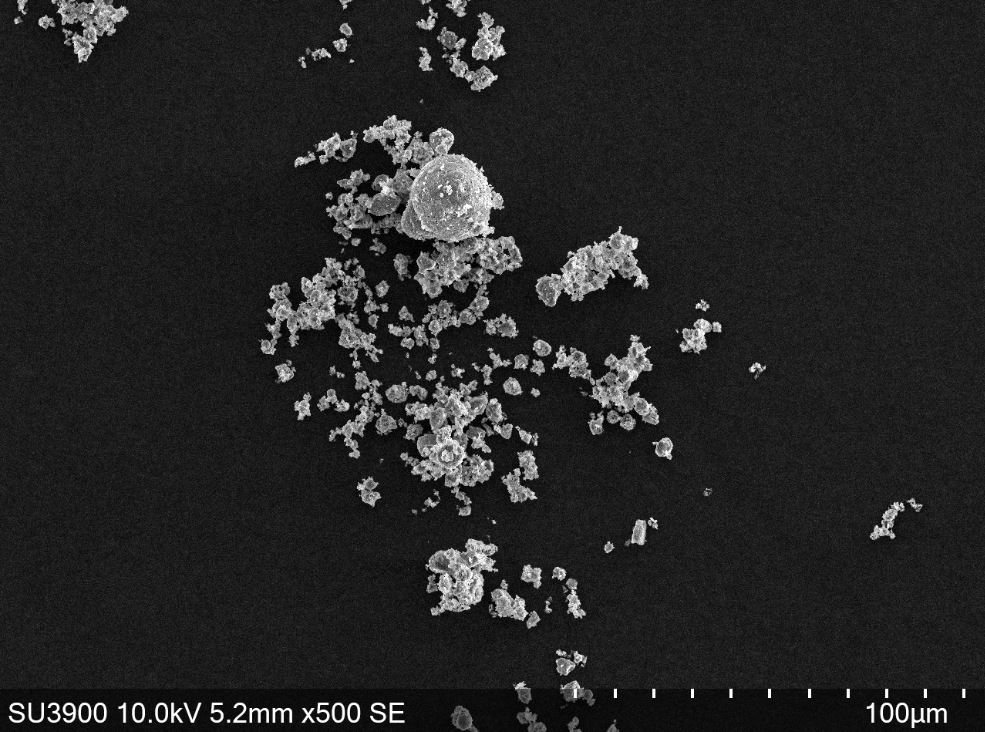

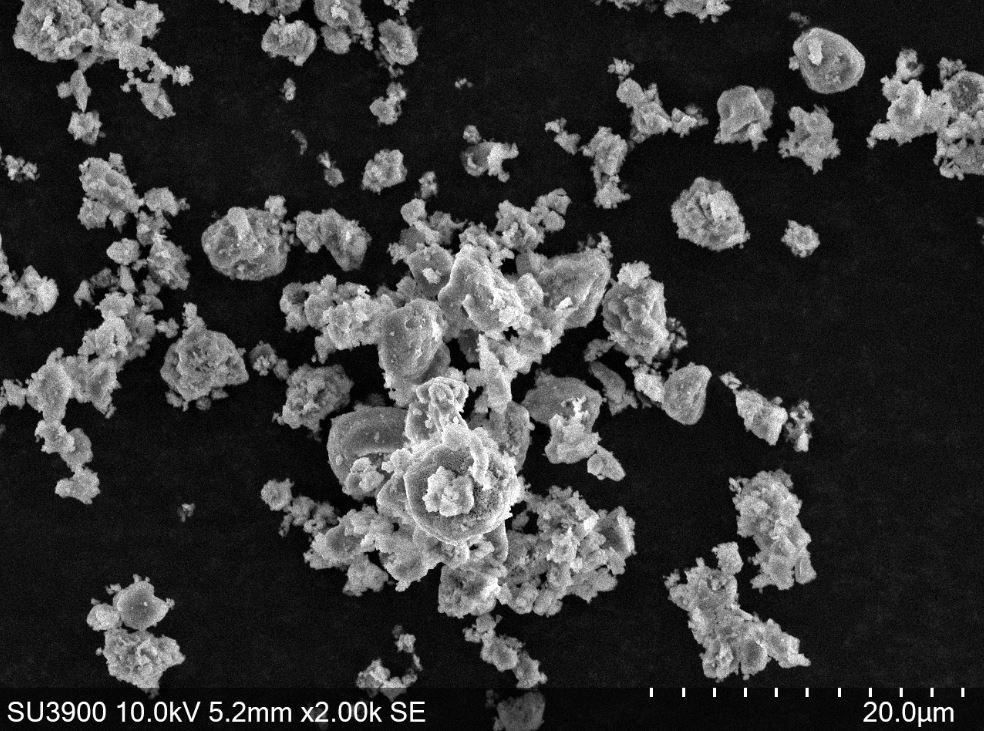

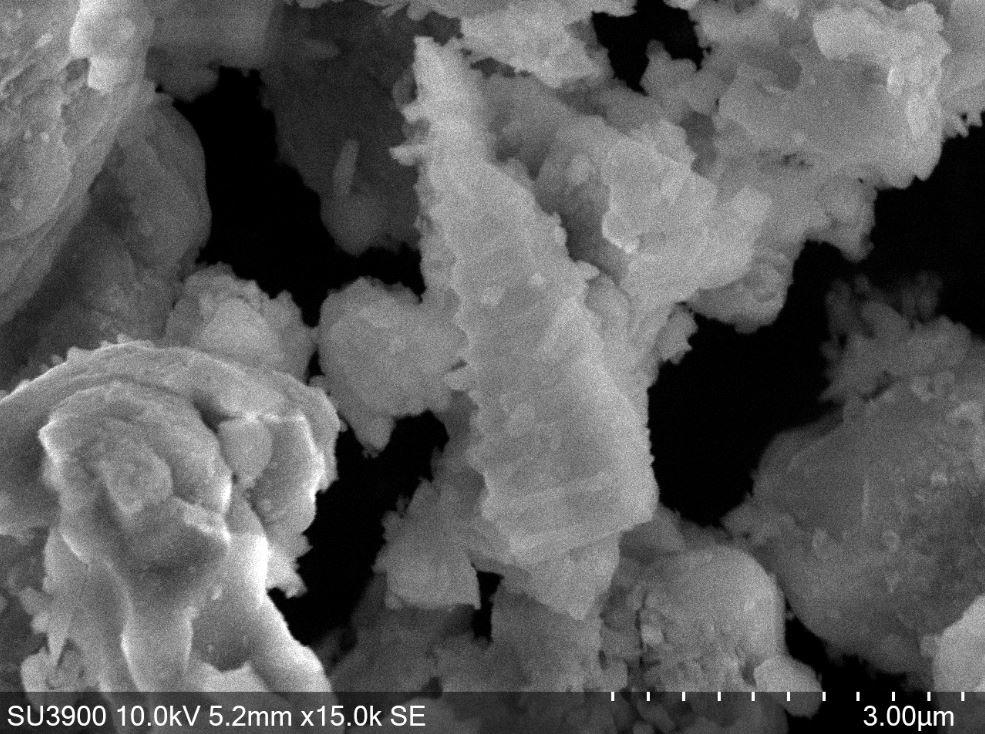

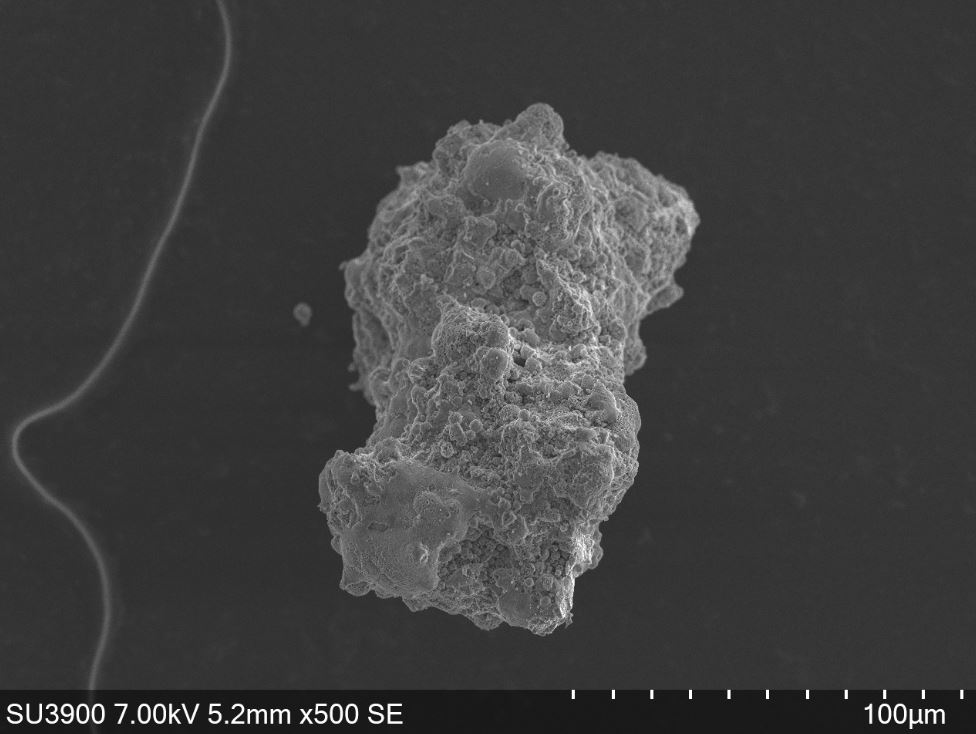

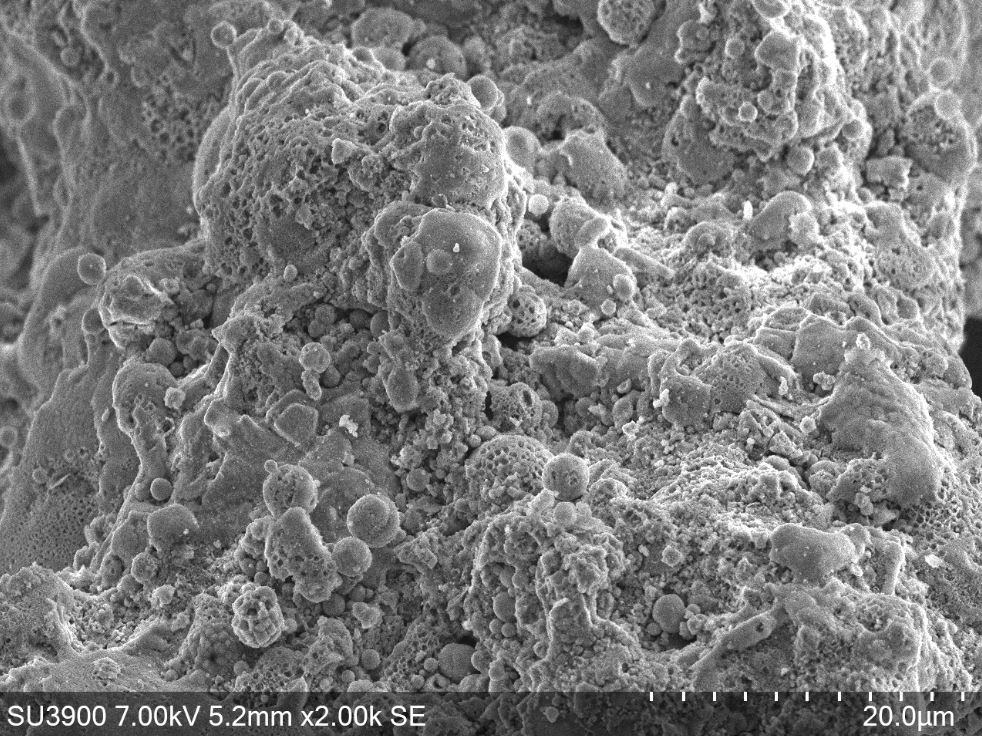

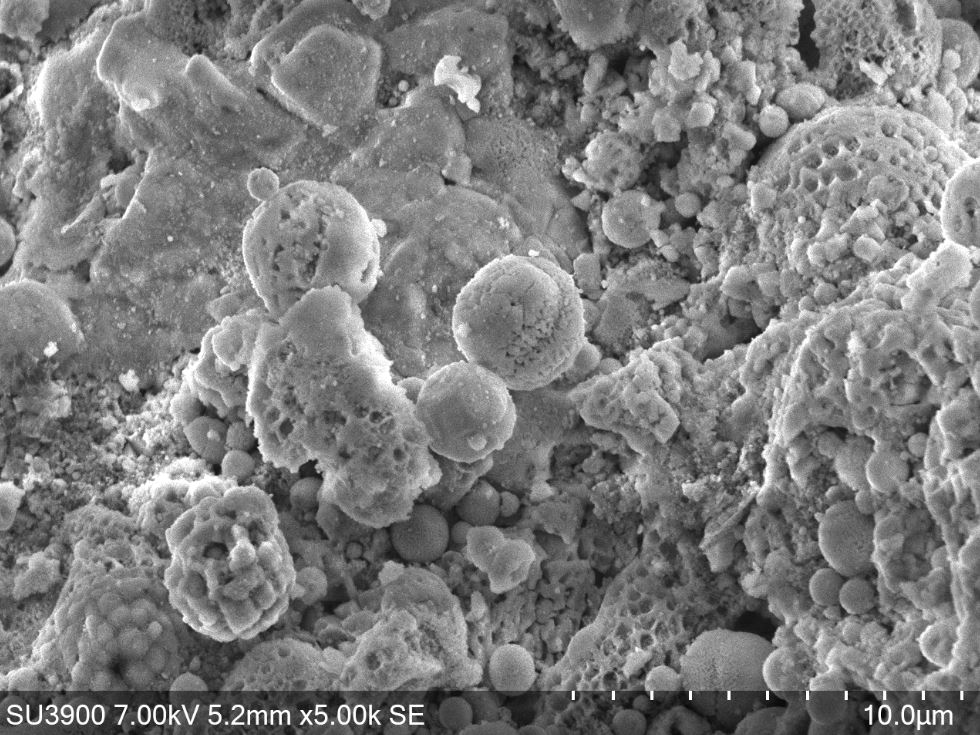

Microscopy: These pictures show the diversity of particle morphologies in our spinel powders and how this material is loaded with small, hard and sharp abrasive edges.

|  |

| Micronized Spinel | Higher Magnification |

|  |

| Many Rough Edges | Complex Structures |

|  |

| CDP Spinel Particle | Higher Magnification |

|  |

| Many Rough Edges | Complex Structures |

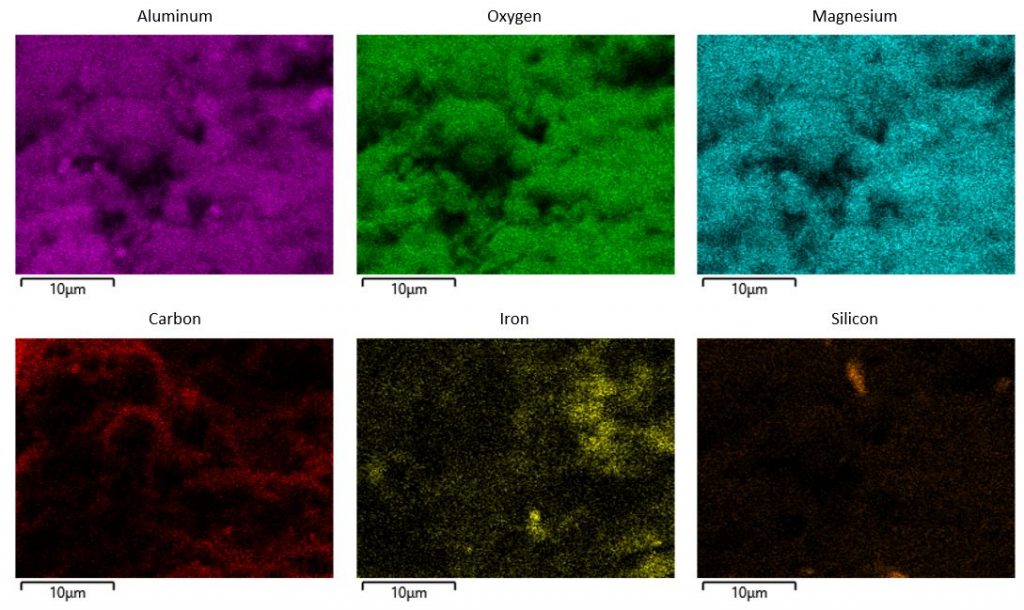

XRD Analysis:

Note that the graphitic/diamond regions are not detectable in XRD due to the low concentration of and particle size of the carbon phases trapped within dominant oxide phases.

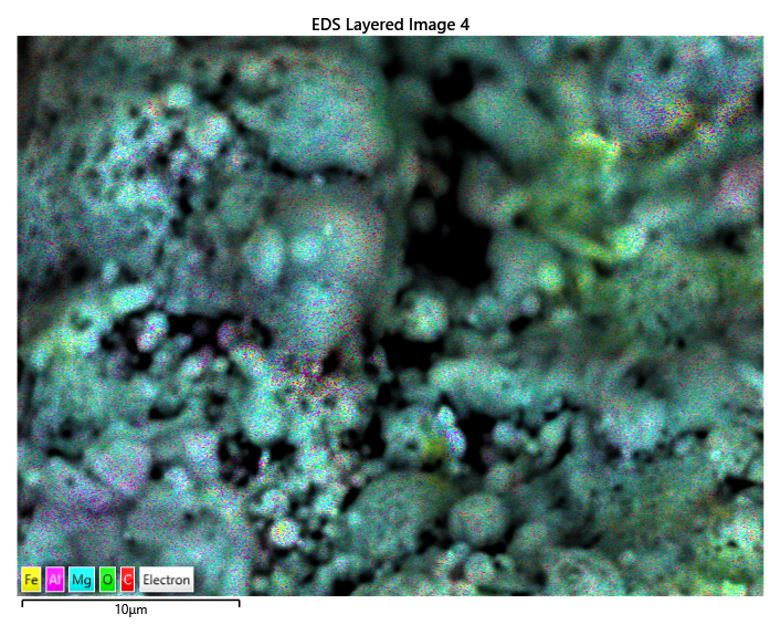

Elemental Mapping: